General Features

Models Specifications

General Features

|

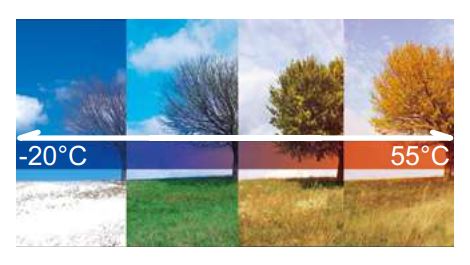

Wide Operation Range No matter in hot summer or cold winter, VRF-X can supply comfortable environment for users. |

|

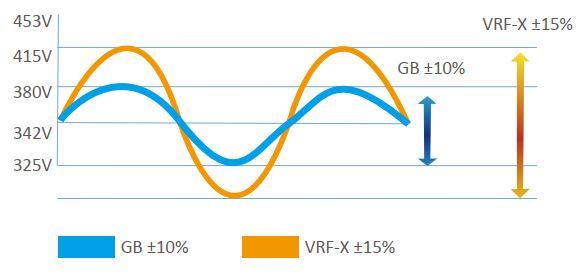

Wide Voltage Design In countries with unstable voltage, VRF-X system could still run stably. |

|

|

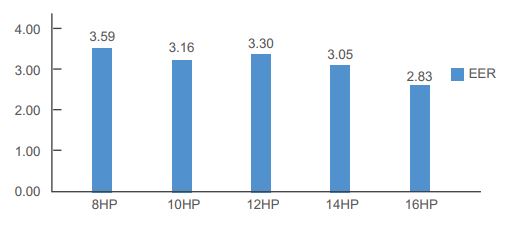

High EER VRF-X tropical series have an excellent energy efficiency in cooling mode by utilizing all DC inverter compressors. At T3 condition the maximum cooling EER can reaches up to 3.59.

|

|

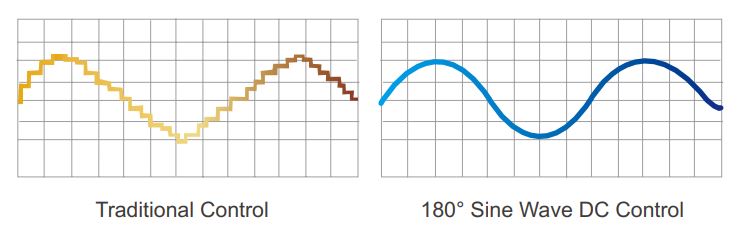

180° Sine Wave Control DC inverter compressor uses 180° sine wave vector control technique that makes the motor operates smoothly and increases the efficiency. Significantly compared with the traditional sawtooth wave, it can also lower the noise level.

|

|

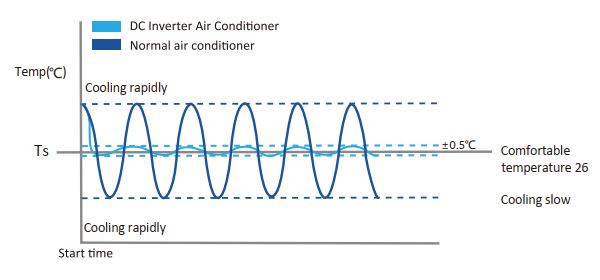

Precise Temperature Control Humanization Design WARTH composite temperature control technology, can detect the indoor/outdoor operation condition and adjust the outdoor output power and optimize the indoor air distribution. This can achieve the high precision adjustment of 0.5°C. |

|

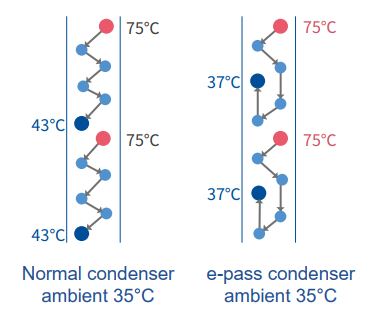

2-stage Sub-cooling Technology The first stage sub-cooling process took place due to the optimized refrigerant circuit and “Inverse fin type” window fin design. The second stage sub-cooling process took place by a high efficiency plate heat exchanger with a sub-cooling EXV. |

|

|

|

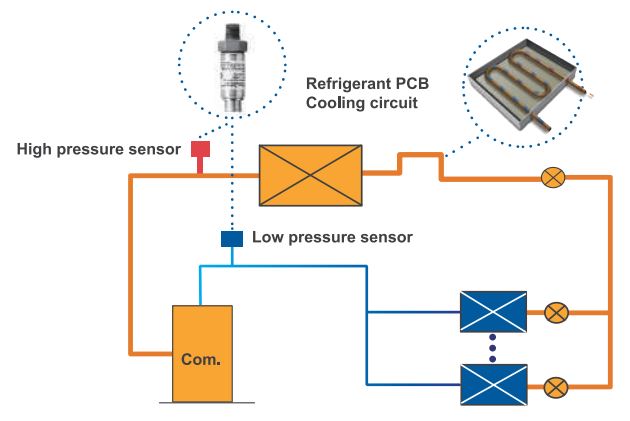

Refrigerant PCB Cooling System The PCB is well cooled by the refrigerant, ensuring the system operate steadily even in tropical area. Frequency limits of the inverter compressor can be relaxed, so that the output capacity of ODU can be higher than conventional products. |

|

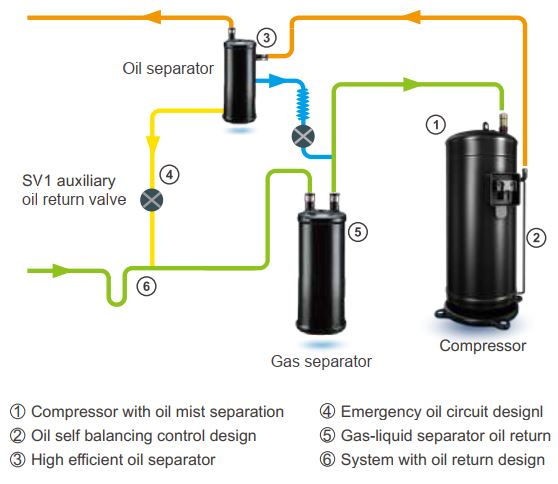

Oil Return Control Technology Dynamic Oil Return Control Technology 6-Step Oil Separating Technology Compressor Throwing Oil Technology |

|

|

No Oil Balance Pipe Between ODUs High efficient oil/gas separating technology can achieve oil balance of the system between the compressors without the oil balance pipe. |

|

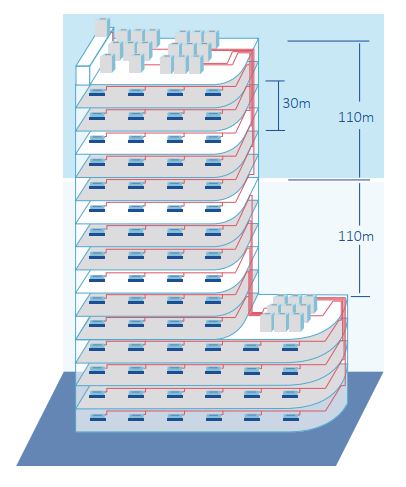

Long Piping Length Thanks to the DC inverter control technology and the sub-cooling circuit technology ,it is possible to design systems with longer piping and elevation for easy installation. Max. Total piping length — 1000 m |

|

|

360° Pipe-connecting Mode VRF-X series can be connected to the refrigerant pipes from the front, left side and right side for the free pipe direction. |

|

Auto Refrigerant Recycling & Auto Refrigerant Charging Refrigerant can be recycled to the outdoor units or indoor units whenever maintenance is needed. The outdoor unit can adjust the refrigerant amount according to the operation parameters such as pressure and temperature, and remind the installation personnel to stop charging. |

|

|

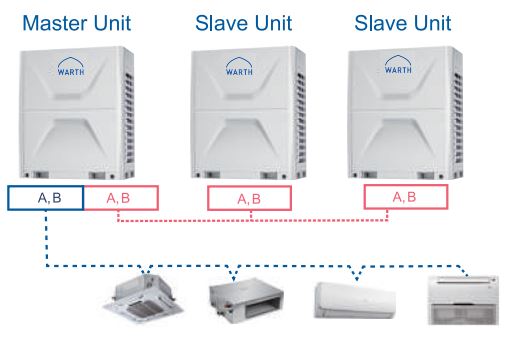

Non-Polar Communication No polar in communication wire ,easy installation and commissioning. |

|

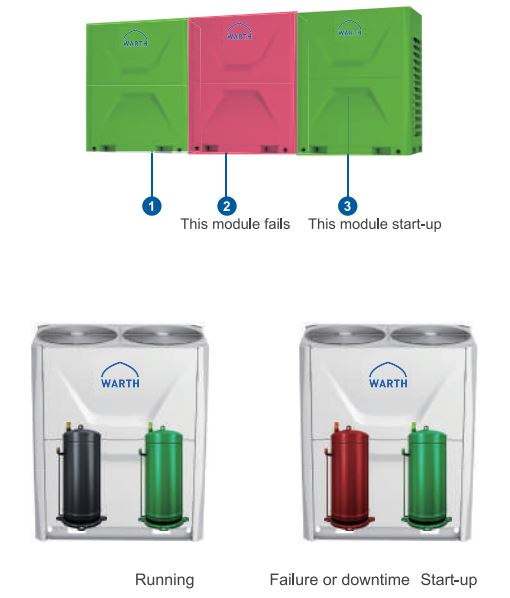

Back-Up Operation Technology Module Emergency As one module breaks down, module emergency can be set, then the rest modules in same combination can run normally. Compressor Emergency As one compressor breaks down, compressor emergency can be set, then another compressor in this unit can run normally. |

|

|

Auto Dust Removal Auto Dust Removal function is optional for VRF-X Tropical series, the outdoor fan can rotate in an opposite direction to remove the dust on the heat exchanger, and the system can operate steadily in severe environment without manual cleaning.

|

|

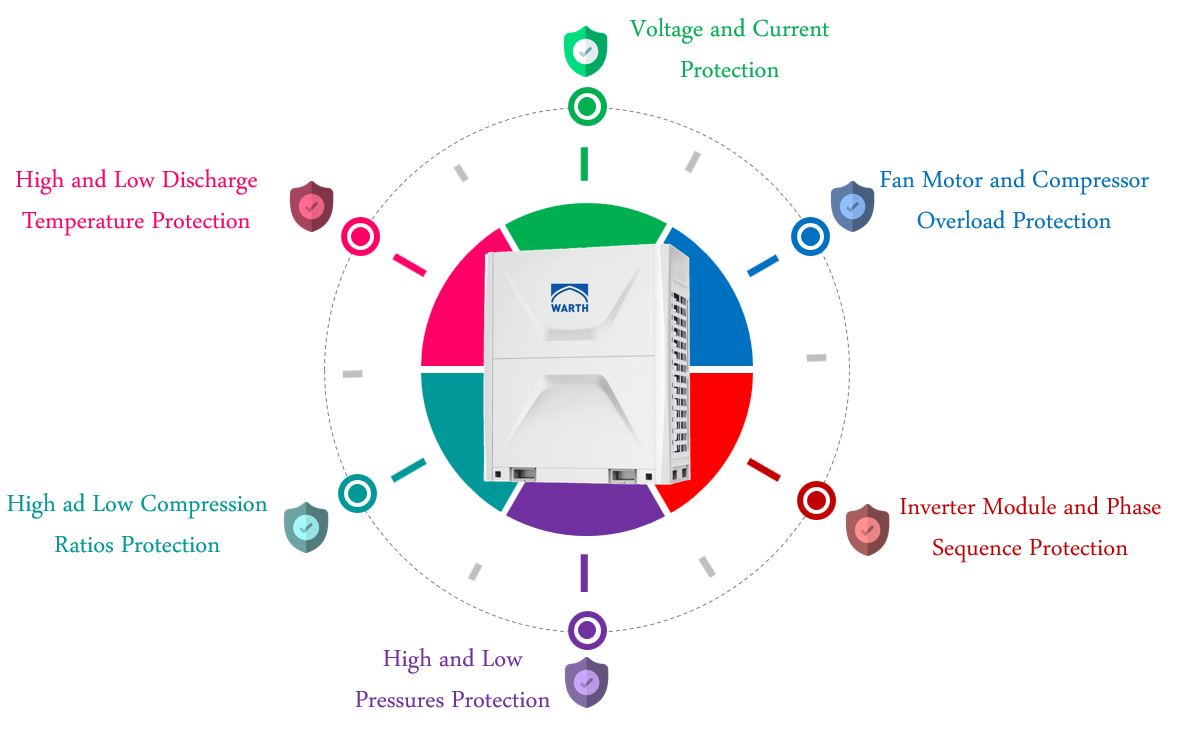

All-round Protection

|

Models Specifications

|

VRF-X Tropical Series |

|||||

|

Model |

WVH08FNRS-A |

WVH10FNRS-A |

WVH12FNRS-A |

WVH14FNRS-A |

WVH16FNRS-A |

|

Horse Power (HP) |

8 |

10 |

12 |

14 |

16 |

|

Cooling Capacity (T1) (kW) |

25.2 |

28 |

33.5 |

40 |

45 |

|

Cooling Capacity (T3) (kW) |

22.3 |

24.9 |

30.5 |

35.7 |

38.7 |

|

Heating Capacity (kW) |

28 |

31.5 |

37.5 |

45 |

50 |

|

Power Supply (V, Hz, Ph) |

380-415, 50/60 ,3 |

380-415, 50/60 ,3 |

380-415, 50/60 ,3 |

380-415, 50/60 ,3 |

380-415, 50/60 ,3 |

|

Cooling Input (T1) (kW) |

5.73 |

6.78 |

8.09 |

9.41 |

11 |

|

EER (T1) |

4.4 |

4.15 |

4.13 |

4.24 |

4.1 |

|

Cooling Input (T3) (kW) |

6.2 |

7.87 |

9.24 |

11.73 |

13.68 |

|

EER (T3) |

3.59 |

3.16 |

3.3 |

3.05 |

2.83 |

|

Heating Input (kW) |

6.17 |

7.07 |

8.65 |

10 |

11.61 |

|

COP |

4.54 |

4.45 |

4.34 |

4.5 |

4.31 |

|

Air Flow Volume (m3/h) |

12000 |

12000 |

14000 |

14000 |

16000 |

|

Sound Level (dBA) |

≤ 58 |

≤ 58 |

≤ 63 |

≤ 63 |

≤ 63 |

|

DC Compressor Quantity |

1 (Inverter) |

1 (Inverter) |

1 (Inverter) |

2 (Inverter) |

2 (Inverter) |

|

DC Fan Motor Quantity |

1 |

1 |

2 |

2 |

2 |

|

Dimensions (WxDxH) (mm) |

990x765x1636 |

990x765x1636 |

1340x765x1635 |

1340x765x1635 |

1340x765x1635 |

|

Weight (kg) |

230 |

230 |

265 |

330 |

330 |

|

The above standard single units can be combined together to reach the capacity up to 64 HP. |

|||||